News

Site Editor

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

The precision of the laser is incredibly accurate since the deformation of the object is kept to a minimum and object distortion is negligible, resulting in extremely pleasing aesthetic outcomes.

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

The precision of the laser is incredibly accurate since the deformation of the object is kept to a minimum and object distortion is negligible, resulting in extremely pleasing aesthetic outcomes.

Benefits of Laser Welding Machine

Views: 707

Author: Site Editor

Publish Time: 2022-03-28

Origin: Site

Recently, the use of laser welding technology has been rapidly encouraged in the development of the welding industry. It has been applied to diverse enterprises be it large, medium or small sized.

As the name implies, laser welding machine is a welding method that employs the use of high energy laser beam to obtain thin-walled and deep precision welds.

The principle of operation involves the transfer of heat energy through heat conduction from the laser beam directly to the atoms of the material to be wielded.

This causes the melting of the material and hence welding is achieved. Laser welding machine can be used to carry both large scale and small scale welding jobs.

Let’s see together the advantages of using a laser welding machine for most of your welding jobs!

The laser is of tremendous benefits to carry out many welding jobs based on the following discussed factors.

However, it is crucial to note that to enjoy these benefits, getting a laser welding machine from a reliable supplier is important. Let’s look at these beneficial factors!

Versatility of laser welding machine

Depending on what you need the laser welding machine to weld, your needs can be achieved.

The laser can be used to work on small portions of objects and also on large thickness objects.

The laser welding machine is so versatile that its laser beam intensity can be modified to weld several different materials where necessary.

Operation speed of the machine

Using a laser welding machine for your welding jobs is advantageous as it allows the welding to be carried out in faster time.

The high operation speed is as a result of the alternative process occurring during operation called as microflame.

Microflame is the process of concentration of the laser beam energy in a small amount of the material to be wielded on.

This makes it possible to obtain excellent results with minimal investment of laser energy beam.

With the use of laser welding machine, you can avoid sequential thermal treatment associated with the welding process.

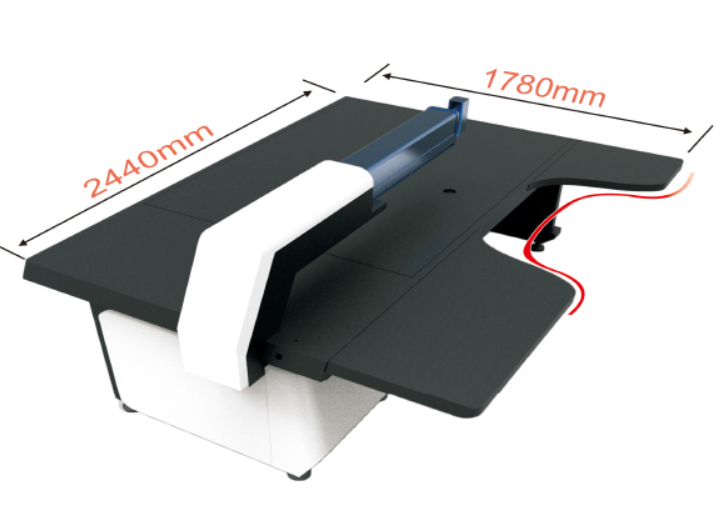

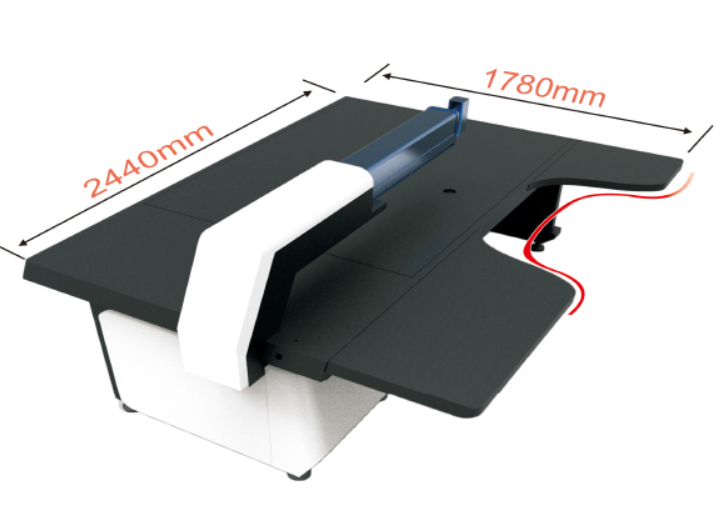

Precision of the machine

The capacity of the laser welding machine allows it to function exceedingly accurately thereby giving highly pleasing aesthetic results.

The precision of the laser is incredibly accurate since the deformation of the object is kept to a minimum and object distortion is negligible, resulting in extremely pleasing aesthetic outcomes.

Effectiveness of the laser welding machine

The welds formed with the laser are exceedingly durable, and the speed with which they are made has no effect on the end result's firmness.

Safety of the machine

Unlike other methods, laser welding allows you to produce a welding without having to heat the entire object to be treated.

It is also possible to intervene on extremely delicate objects (for example, antique jewelry) in this manner without risking any damage to them or reducing the effectiveness of the intervention.

Are you in need of a high quality laser welding machine?

Using a laser welding machine at your workshop will ease your tasks and give you your desired outcome.

If you're interested in owing one from a reliable manufacturer, consult our catalog or contact us for more detailed information on the qualities and performance of our laser welding devices!