News

Site Editor

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Looking at getting a laser cutting machine that suits your needs, do contact a reputable manufacturer for a satisfying product.

Site

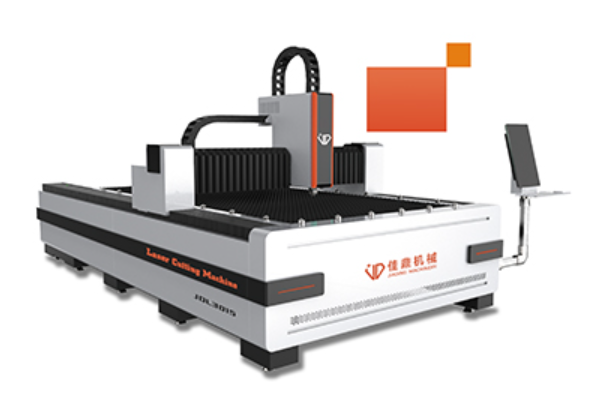

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Looking at getting a laser cutting machine that suits your needs, do contact a reputable manufacturer for a satisfying product.

Component of Fiber Laser Cutting Machine

Views: 763

Author: Site Editor

Publish Time: 2022-05-07

Origin: Site

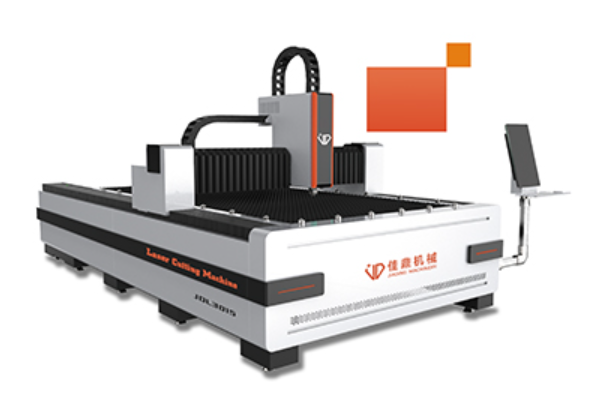

Mainly, the fiber laser cutting machines is focused on the outward part of the workplace, therefore if the extreme concentration part on the machine is exposed, the area will be melted immediately and turn to vapor.

Laser cutting machines has substituted the outdated knife through an unseen beam. Its features include, high accuracy, fast cutting, not restricted to the pattern of cutting, automatic typesetting, smooth cutting, saving of material.

Its performance has a very high speed, it has an very adaptation rate and other benefits has created it extensively useful in the machinery industrial, midst where the most standard are cutting of sheet metal, electric cupboard, car field, and more.

Looking at getting a laser cutting machine that suits your needs, do contact a reputable manufacturer for a satisfying product.

Some basic components of fiber laser cutting machine

-

Fiber laser cutting supplier

This is the utmost essential factor of fiber cutting machine. It is the ‘power source’ that allows fiber cutting machine to carry out its cutting operations.

Fiber laser is highly preferred to other types of lasers due to its developed efficiency, facility life, it has a fewer care, lower cost compared to others.

Servo moto is defined as a machine that regulate the process of mechanical element in the service system. It can support motor indirect peed change device.

The servo motors regulate the rapidity and positioning very accurately, and also change the signal of the voltage into rotating and to drive the regulate object.

The high-grade servo motor can also successfully make sure that the cutting precision, putting rapidity and replication putting precision of the laser machine.

Air cutting scheme of fiber cutting machine mostly comprises of air compressor, filter maneuver and also air dryer. Between them, there are mainly two types of air basis: air bottled and air compressor.

Air cutting scheme is economically better than previous gas cutting, the purpose of using air cutting is to protect gas expenditure cost compared to Nitrogen.

This is a laser output device consisting mainly of focus tracking system, focus lens and nozzle

The height of the laser cutting machine head is adjustable, thus can be controlled for use for different materials and cutting parameters such as material thickness.

It mostly regulate the entire core components of the machine tool, understand the movement of X, Y, Z axis, and also regulate the output control of the laser.

It harmonizes the operation of the devices of the laser cutting system.

The chiller simply serves the purpose of rapidly and effectively cooling the laser source, laser head and other core devices of the laser cutting machine.

It contains input and output control device switches, which executive progressive functions of cooling water flow, extreme temperature alarms, and their performance is stable.

The host is collectively made up of the bed, beam and Z-axis system of the laser cutting machine.

During the laser cutting machine performance, put the workpiece on the bed, then use the servo motor to drive the beam so as to control the movement of the Z- axis. Note that the parameters can be adjusted to suit the user’s needs.

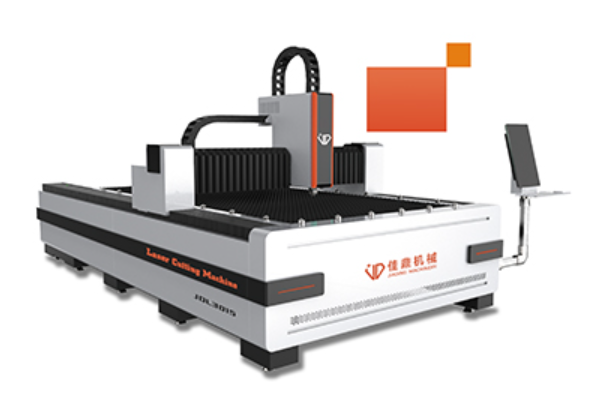

Do you wish to get a durable fiber laser cutting machine?

When choosing a fiber laser cutting machine, do not just consider the characteristics of the product materials only.

You should also consider the performance of the laser equipment, so that you can find the laser equipment suitable for your industry products.

We focus on providing customer high quality reliable equipment, for more details please click here.