News

Site Editor

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Laser cutting is to irradiate the workpiece with a focused high-power density laser beam to quickly melt, vaporize, ablate or reach the ignition point of the irradiated material. At the same time, the molten material is blown away by the high-speed airflow coaxial with the beam to realize the cutting of the workpiece. Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture.

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Laser cutting is to irradiate the workpiece with a focused high-power density laser beam to quickly melt, vaporize, ablate or reach the ignition point of the irradiated material. At the same time, the molten material is blown away by the high-speed airflow coaxial with the beam to realize the cutting of the workpiece. Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture.

Fiber Laser Cutting VS. Water Cutting

Views: 587

Author: Site Editor

Publish Time: 2021-11-22

Origin: Site

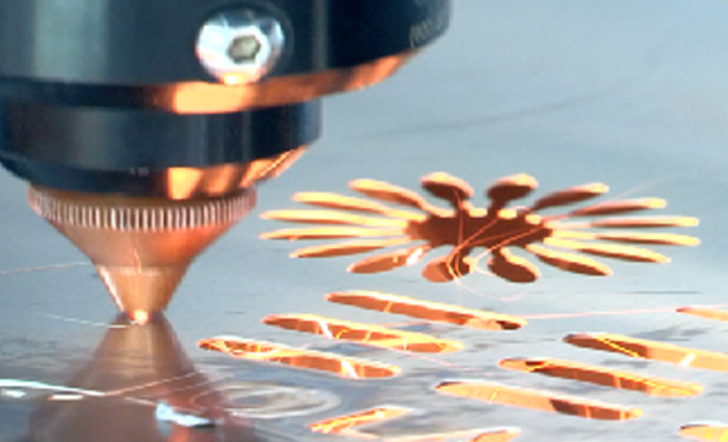

Laser cutting is to irradiate the workpiece with a focused high-power density laser beam to quickly melt, vaporize, ablate or reach the ignition point of the irradiated material. At the same time, the molten material is blown away by the high-speed airflow coaxial with the beam to realize the cutting of the workpiece. Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture.

Water cutting, also known as water jet, is a high-pressure water jet cutting technology. It is a machine that uses high-pressure water to cut. Under the control of the computer, the workpiece can be sculpted at will, and it is not affected by the texture of the material. Because of its low cost, easy operation, and high yield rate, water cutting is gradually becoming the mainstream cutting method in industrial cutting technology. Water cutting is divided into two methods: no sand cutting and sand cutting.

So, what are the differences and advantages of fiber laser cutting compared with water cutting?

Analysis of the difference and advantages of fiber laser cutting compared with water cutting:

1. The application range of fiber laser cutting compared with water cutting:

The laser cutting machine has a wide range of applications. Regardless of metal or non-metal, it can cut and cut non-metal, such as cloth, leather, etc. You can use a CO2 laser cutting machine. For cutting metal, you can use a fiber laser cutting machine. The plate deformation is small.

Water cutting is cold cutting, no thermal deformation, good quality of the cutting surface, no secondary processing, and easy secondary processing if necessary. Water cutting can perforate and cut any material (including reflective materials, composite materials, sensitive materials,that are not or difficult to cut by lasers,such as stones, alloys, etc.). The cutting speed is fast and the processing size is flexible.

2. The speed and surface quality of fiber laser cutting compared with water cutting:

Advantages of fiber laser cutting: fast cutting speed, can be used for mass production; high processing accuracy, good repeatability, without damaging the surface of the material; it can cut the entire board with a large format without opening a mold, which is economical and time-saving; not limited to the cutting pattern, automatic typesetting saves materials, the cut is smooth, and the processing cost is low.

Disadvantages of water cutting: the speed is quite slow, not suitable for mass production.

The surface roughness of laser cutting is not as good as water cutting, the thicker the material, the more obvious. Water cutting will not change the texture of the material around the cutting seam (laser is a thermal cutting and will change the texture of the cutting area).

3. The production investment of fiber laser cutting compared with water cutting:

The price of the laser cutting machine is different with the power size, and the price is between hundreds of thousands to several million.

Different models of laser cutting machines have different prices. Cheap ones such as carbon dioxide laser cutting machines cost only 20,000 to 30,000, and expensive ones such as 1000W fiber laser cutting machines now cost more than one million. Laser cutting has no consumables, but the equipment investment cost is the highest among all cutting methods.

The cost of water cutting equipment is second only to laser cutting. It has high energy consumption and high maintenance costs. The cutting speed is not as fast as laser cutting. All abrasives are disposable, and they are discharged into the nature after they are used once. The environmental pollution caused is also serious.

In need of a fiber laser cutting machine

Jiading Equipment Technology Co., LTD., a professional supplier which is specializing in laser marking & cutting technology for more than15 years. We strive to make our product quality and our service invincible in the market. Our products include fiber laser cutting machine, CO2 laser cutting machine, laser welding machine, laser engraving & marking machine and related supporting machine. If you have any inquiry, please do not hesitate to contact us.