News

Site Editor

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

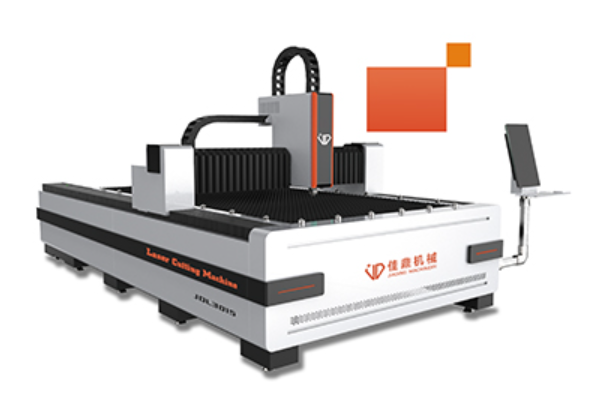

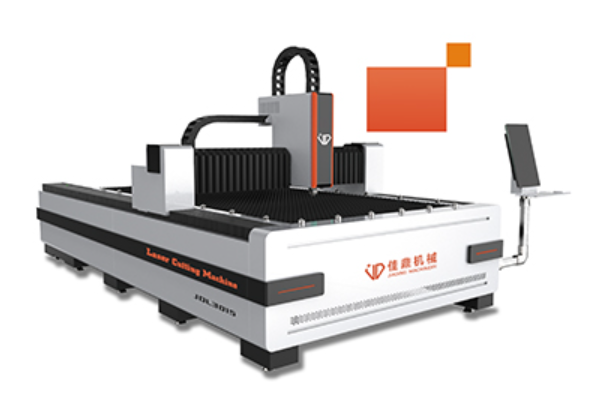

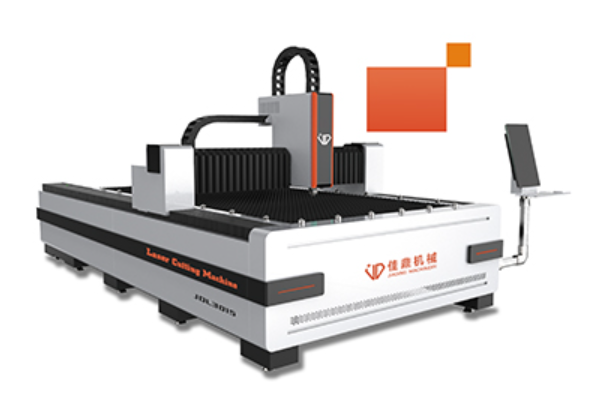

Are you wondering about the operation principles of the fiber laser cutting machine? Do not stress too much as this article will give you a broad view of how you can operate the fiber laser cutting machine.

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Are you wondering about the operation principles of the fiber laser cutting machine? Do not stress too much as this article will give you a broad view of how you can operate the fiber laser cutting machine.

How to Operate a Fiber Laser Cutting Machine

Views: 761

Author: Site Editor

Publish Time: 2022-06-07

Origin: Site

Cutting technology is said to be in demand and has positively contributed to technological advancement. Working on metals using cutting technologies has prompted research for an improvement for enhanced preferences that have lower environmental effects.

Having seen the need for an upgrade to the CO2 laser-cutting machine that was first produced in the 1980s, technological researchers found out that the newer model, the fiber laser cutting machine, proves a better option.

Are you wondering about the operation principles of the fiber laser cutting machine? Do not stress too much as this article will give you a broad view of how you can operate the fiber laser cutting machine.

What is a fiber laser cutting machine?

Fiber laser cutting machines are mechanical devices that facilitate the treatment of metallic sheets and other metal applications such as electronic and electrical equipment, cooking utensils, tool wear, and other industrial machinery and equipment.

Fiber laser cutting machines, unlike other types of cutting machines, can cut both metal and non-metal materials such as wood, paper, plastic, natural and synthetic, as well as aluminum and its alloys, iron pipes, and stainless steel.

Other applications include leather, pottery, quartz, and other natural materials.

Operation of a Fiber Laser Cutting Machine

Operating a fiber laser cutting machine is not as hard as it is assumed to be. It only requires some training.

Below is the operation procedure for a fiber laser cutting machine.

1. Material Selection

Before you think of how to operate the fiber laser cutting machine, there is a need for you to consider the type of material that would be worked on.

In addition, there is a need to check out the stability of the material to avoid any error that can affect the accuracy of cutting.

2. Setting up the fiber laser cutting machine for work

Next is to set up the fiber laser cutting machine for work. Afterward, the machine is set to the desired cutting pattern for the material time to be worked on.

Other variables that need to be checked out include thickness, and dimensions, among others.

Following this, the cutting head of the machine is then focused on the area that you want to cut.

3. Regulate the fiber laser cutting machine

Having set up the fiber laser cutting machine for work, the next line of action is to regulate some properties of the machine such as the water pressure and temperature and the chiller in the machine.

4. Initiate operation of the laser

Finally, initiate the laser to start its cutting operation while sorting the cut materials into various categories.

Contact us for Fiber Laser Cutting Machine

No doubt, a fiber laser cutting machine is a better option when assessed alongside a CO2 cutting machine and other forms of cutting technologies. This has caused many metal fabricators to subscribe to the usage of the fiber laser cutting machine.

Therefore, in case you are interested in purchasing a fiber laser cutting machine, kindly reach out to us to get yours at affordable prices.

Contact us today for your highly efficient and cost-effective fiber laser cutting machine.