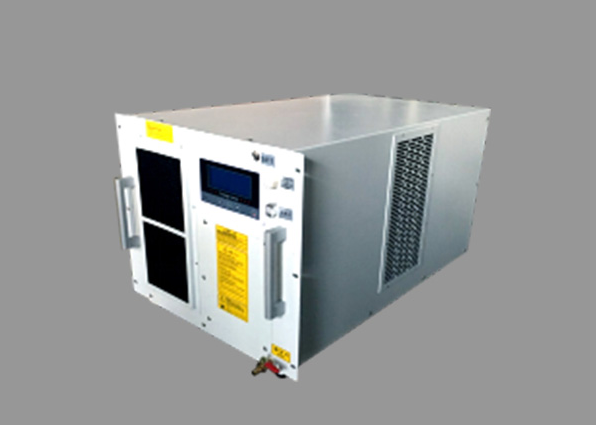

INTEGRATED CABINET

- Small footprint, easy to move and use

- Strong comprehensive performance

- Wide application field

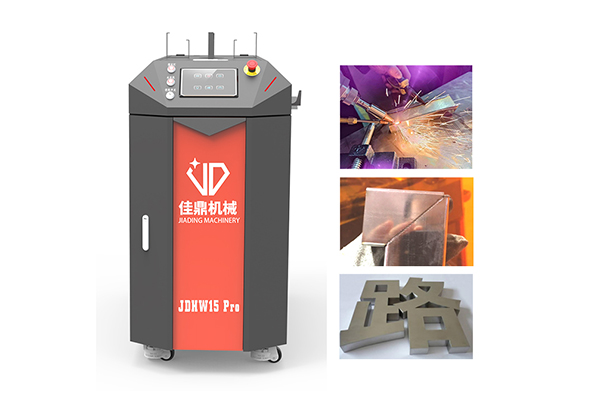

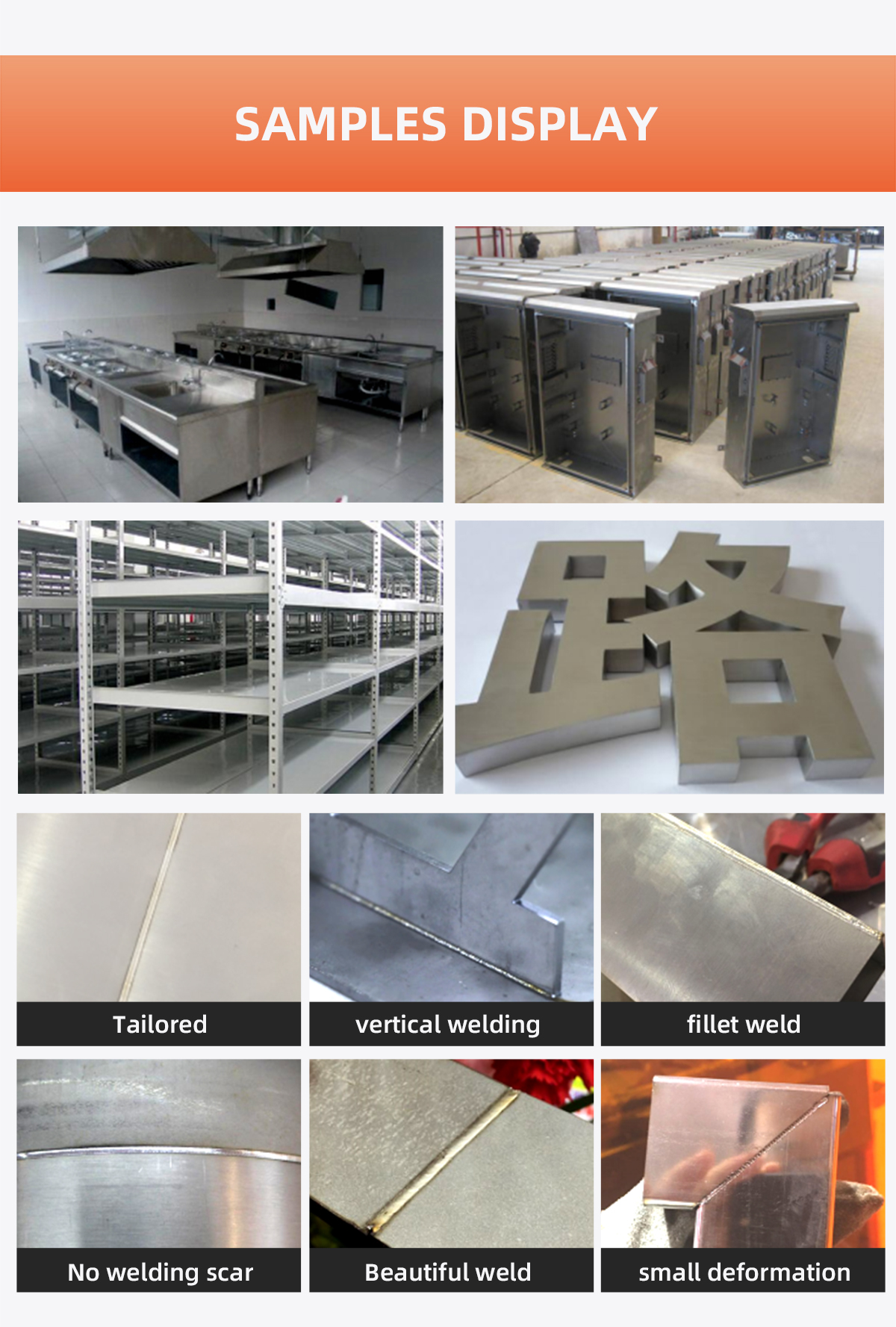

JDHW20Pro fiber laser welding machine application in Stainless steel, Carbon steel, Aluminum, Copper materials, etc. Beautiful weld, fast speed, no consumables, no welding mark, no discoloration, no need to polish later. It can be configured with a variety of Angle nozzle to meet the welding needs of different products.

Fast welding speed, 2~10 times faster than traditional welding.

Easy operating no needs training

Welding seam beautiful smooth and beautiful, don’t need polish, save your time.

No deformation or welding scar, firm welding of the workpiece.

Laser welding has less consumables and long service life.

Safer, more environmentally friendly.

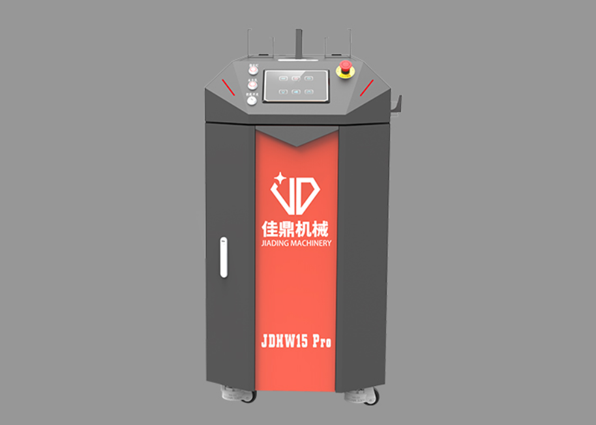

| JD HW 10/15/20PRO | ||

|---|---|---|

| MODEL NO. | JDHW10Pro | JDHW20Pro |

| Laser power | 1000W | 2000W |

| Wave length | 1070nm | |

| Fiber core | 20μm | |

| Fiber rope length | 10m | |

| Working way | Continuous | |

| Galvo Width | 0.5-6mm | |

| Scanning speed | ≤8000mm/s | |

| Welding speed | 0-120mm/s | |

| Cooling system | Smart dual temperature chiller | |

| Working temperature | 15-35℃ | |

| Working environment humidity | <70%, no condensation | |

| Welding seam tolerance | ≤0.5mm | |

| Power | AC220V/50Hz/7KW | AC3800V/50Hz/11KW |

| Air Source | 0.15-0.2MPa | |

| Working space | L135*W60*H130cm | |

| PACKING | Export Wooden Case | |

| Total Weight | G.W.290KGSN.W.240KGS | |

| Export Wooden Case | L175*W75*H145cm | |

| PENETRATION DATA | |||||||

|---|---|---|---|---|---|---|---|

| material | Protective gas | thickness | 500W | 750W | 1000W | 1500W | 2000W |

|

Stainless steel |

Ar | 0.5 | √ | √ | √ | √ | √ |

| 0.8 | √ | √ | √ | √ | |||

| 1.0 | √ | √ | √ | √ | |||

| 1.2 | √ | √ | √ | √ | |||

| 1.5 | √ | √ | √ | ||||

| 2.0 | √ | √ | |||||

| 2.5 | √ | ||||||

| 3.0 | √ | ||||||

| carbon steel | Co2 | 0.5 | √ | √ | √ | √ | √ |

| 0.8 | √ | √ | √ | √ | √ | ||

| 1.0 | √ | √ | √ | √ | |||

| 1.2 | √ | √ | √ | ||||

| 1.5 | √ | √ | √ | ||||

| 2.0 | √ | √ | |||||

| 2.5 | √ | ||||||

| 3.0 | √ | ||||||

| carbon steel | Co2 | 0.5 | √ | √ | √ | √ | √ |

| 0.8 | √ | √ | √ | √ | √ | ||

| 1.0 | √ | √ | √ | √ | |||

| 1.2 | √ | √ | √ | ||||

| 1.5 | √ | √ | √ | ||||

| 2.0 | √ | √ | |||||

| 2.5 | √ | ||||||

| 3.0 | √ | ||||||

| Galvanized sheet | Ar | 0.5 | √ | √ | √ | √ | √ |

| 0.8 | √ | √ | √ | √ | √ | ||

| 1.0 | √ | √ | √ | √ | |||

| 1.2 | √ | √ | √ | ||||

| 1.5 | √ | √ | |||||

| 2.0 | √ | ||||||

| Aluminum | N2 | ||||||

| 1.0 | √ | √ | √ | ||||

| 1.2 | √ | √ | √ | ||||

| 1.5 | √ | √ | |||||

| 2.0 | √ | ||||||

| 2.5 | √ | ||||||

What else do you want to know? Contact us right now!