News

Site Editor

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Depending on the look you are going for on your material and what material you are cutting or engraving, the speed and power settings can be decreased and increased. Testing your material beforehand is a good practice and will get you closer to perfect results, every time.

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Depending on the look you are going for on your material and what material you are cutting or engraving, the speed and power settings can be decreased and increased. Testing your material beforehand is a good practice and will get you closer to perfect results, every time.

The Basics of CO2 Laser Cutting Machine

Views: 615

Author: Site Editor

Publish Time: 2022-01-19

Origin: Site

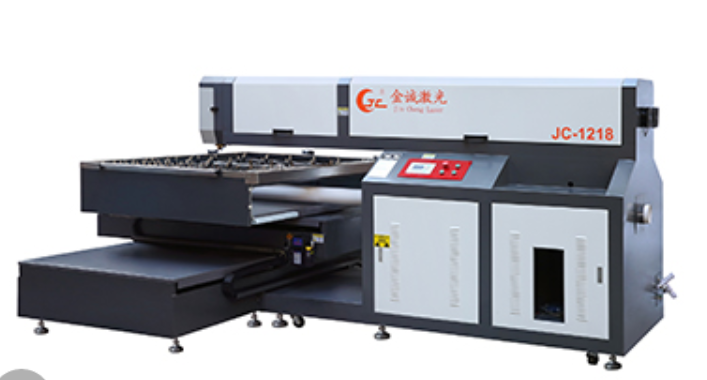

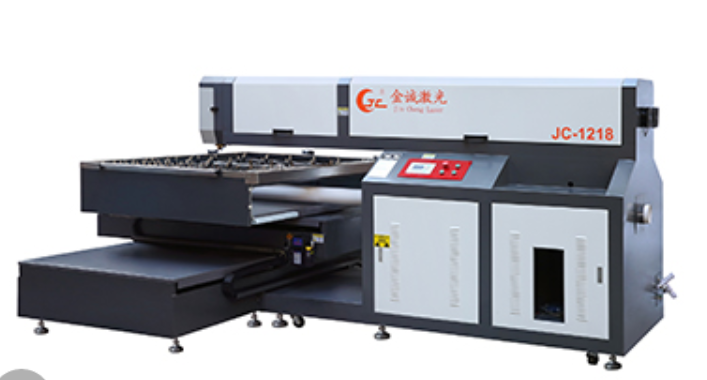

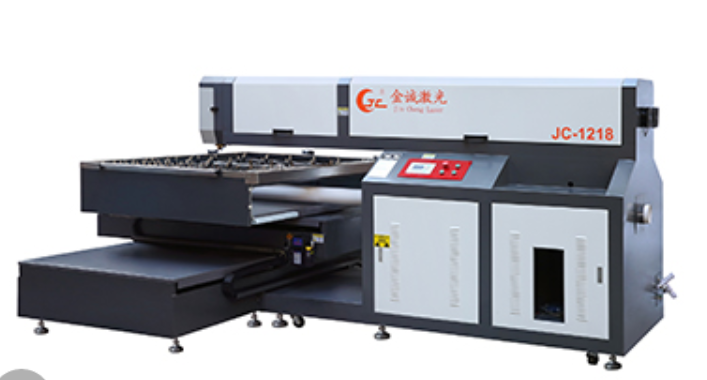

What is CO2 laser cutting machine?

The CO2 laser cutting machine, or CO2 laser cutter is a type of CNC laser machine using CO2 laser technology to cut and engrave materials. As the CO2 laser cutting machine can also engrave, the CO2 laser cutting machine is also called CO2 laser engraving machine or CO2 laser engraver. Besides, some people also call it wood laser cutter or acrylic laser cutter, etc. The CO2 laser cutting machine uses a focusing lens to focus the CO2 laser beam onto the surface of the material to melt it. At the same time, the coaxial compressed gas blows away the molten material. The laser beam moves along a certain path, forming a slit of a certain shape. Then the cutting process completes.

How does a Co2 Laser Work?

Let’s dig into the nitty-gritty. There is a lot of magic (and science!) involved in this tool that will give your business the capability to transform any object into a prized possession.

In a Co2 laser cutter, light is produced when electricity runs through a gas-filled tube with mirrors at both ends. One mirror is fully reflective while the other one lets some light come through. These mirrors guide the laser beam into the material that is to be cut. The gas is typically a mixture of carbon dioxide, nitrogen, hydrogen, and helium.

Any light produced by Co2 lasers is extremely powerful compared to normal light. This is because of the mirrors that bookend the tube of gases. These mirrors reflect most of the light traveling through the tube and cause the light waves to build in intensity. The light only passes through the partially reflective mirror when it becomes bright enough.

Since the light from a laser is infrared, it is invisible to the human eye. It also has a very long wavelength. It can cut a variety of materials, including cloth, wood, metal, glass, and paper. The intense heat from this light vaporizes the material that is going to be cut, leaving an accurate, smooth finish.

Depending on the look you are going for on your material and what material you are cutting or engraving, the speed and power settings can be decreased and increased. Testing your material beforehand is a good practice and will get you closer to perfect results, every time.

The Advantages of Co2 Laser Cutters

There are several benefits to using a Co2 laser cutter.

Non-Contact Process – The beam doesn’t physically touch the material it is working with; instead, it causes the material to melt through intense heat. This causes minimal damage to the material and the machine.

Low Power Consumption – Laser cutter machines have low maintenance costs and only need inexpensive replacement parts.

A Safer Method – Laser cutting is much safer than other forms of cutting since it doesn’t use a blade. The beam itself is sealed in a tight little lightbox.

Incredible Precision – Lasers produce highly accurate and precise cuttings that have clean cuts and a smooth finish.

Many Applications – Laser cutting is not just for manufacturing processes – it can also be used in the medical sector, as well as in the arts.

Looking for a CO2 laser cutting machine?

Jiading Equipment Technology Co., LTD., a professional supplier which is specializing in laser marking & cutting technology for more than15 years.Our products include fiber laser cutting machine, CO2 laser cutting machine, laser welding machine, laser engraving & marking machine and related supporting machine. If you have more questions, please click here to contact us.