News

Site Editor

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

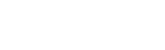

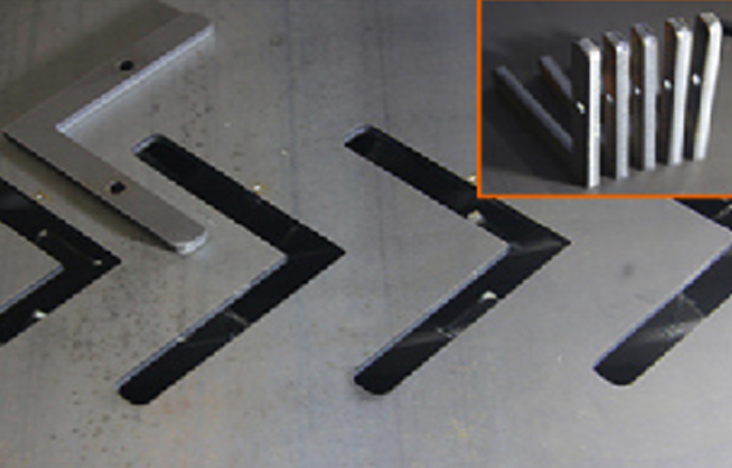

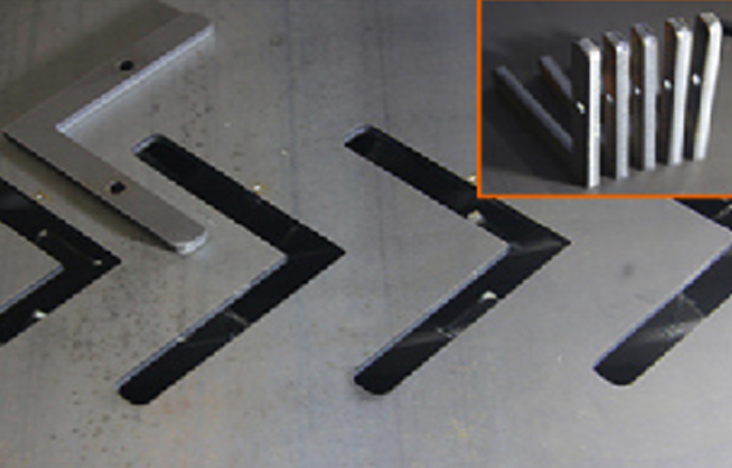

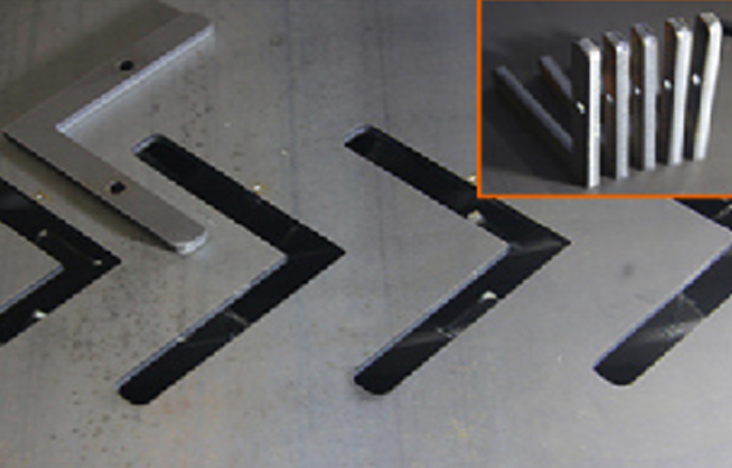

Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting pattern restrictions, automatic typesetting, saving materials, smooth cuts, and low processing costs. It will be gradually improve or replace traditional metal cutting process equipment.

Site

https://jdlasertech.usa18.wondercdn.com/uploads/image/61551c3bea28a.png

Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting pattern restrictions, automatic typesetting, saving materials, smooth cuts, and low processing costs. It will be gradually improve or replace traditional metal cutting process equipment.

What Materials Can The Laser Cutting Machine Cut?

Views: 676

Author: Site Editor

Publish Time: 2022-01-06

Origin: Site

Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting pattern restrictions, automatic typesetting, saving materials, smooth cuts, and low processing costs. It will be gradually improve or replace traditional metal cutting process equipment.

At present, the application directions of laser cutting equipment on the market mainly include the following three categories:

The first category is processing materials used for decoration, advertising, lamps, kitchen utensils, sheet metal parts, electrical cabinets, elevator panels, engineering boards, and high and low switch cabinets. These materials are generally thin. Stainless steel plates with a thickness of 1-5mm materials can be cut with a medium-power laser cutting machine.

The second category is cutting plastic (polymer), rubber, wood, paper products, leather, and natural or synthetic organic materials. Since these items are not metal products, they can absorb laser light differently, so this type of material is best to use CO2 laser cutting machine for cutting.

The third category is low carbon steel and 12mm stainless steel with a thickness of 8-20mm. This type of material requires a high-power laser cutting machine to cut quickly and instantly. You can consider buying a high-power fiber laser cutting machine or high-power CO2 laser cutting machine.

Metal laser cutting machines can process materials. Although almost all metal materials have high reflectivity to infrared energy at room temperature, CO2 lasers emitting 10.6um beams in the far-infrared band are still successfully used in laser cutting of many metals.

Carbon steel

Modern laser cutting systems can cut carbon steel plates with a maximum thickness of up to 20 mm. The cutting seam of carbon steel can be controlled within a satisfactory width range by using the oxidation melting cutting mechanism. The cutting seam for thin plates can be as narrow as about 0.1 mm.

Stainless steel

Laser cutting is an effective processing tool for the manufacturing industry that uses stainless steel sheet as the main component. With strict control of the heat input in the laser cutting process, the heat-affected zone of the trimming can be restricted from becoming very small, thereby effectively maintaining the good corrosion resistance of this type of material.

Alloy steel

Most alloy structural steels and alloy tool steels can be used to obtain good trimming quality by laser cutting. Even for some high-strength materials, as long as the process parameters are properly controlled, straight, non-sticky slag cutting edges can be obtained. However, for tungsten-containing high-speed tool steel and hot mold steel, erosion and slag sticking will occur during laser cutting.

Aluminum and alloys

Aluminum cutting belongs to the melting and cutting mechanism, and the auxiliary gas used is mainly used to blow away the molten product from the cutting area, and usually a better cut surface quality can be obtained. For some aluminum alloys, attention should be paid to prevent the occurrence of micro-cracks between the surface of the slit.

Copper and alloys

Pure copper (red copper) basically cannot be cut with a CO2 laser beam due to its high reflectivity. Brass (copper alloy) uses a higher laser power, and the auxiliary gas uses air or oxygen, which can cut thinner plates.

Titanium and alloys

Pure titanium can well couple the heat energy converted by the focused laser beam. When the auxiliary gas is oxygen, the chemical reaction is fierce, and the cutting speed is faster, but it is easy to form an oxide layer on the cutting edge, and it can cause overburn if you are not careful. For the sake of safety, it is better to use air as the auxiliary gas to ensure the cutting quality. The laser cutting quality of titanium alloy commonly used in the aircraft industry is better. Although there will be a little sticky slag at the bottom of the cut seam, it is easy to remove.

Nickel alloy

Nickel-based alloys are also called super alloys, and there are many varieties. Most of them can be oxidized fusion cutting.

When choosing laser equipment, we must not only consider the characteristics of our own product materials, but also consider the performance of the laser equipment, so that we can find the laser equipment suitable for our industry products. If you have any questions about the equipment, kindly contact us!